Steel Warehouse Construction: Design, Benefits, and Real-World Applications

Steel warehouse construction has become one of the most reliable solutions for industries that require durability, cost-efficiency, and speed in building storage facilities. Unlike traditional brick-and-mortar warehouses, steel structures are designed to withstand heavy use, harsh weather conditions, and constant operations without losing structural integrity.

The rise of global trade, e-commerce, and manufacturing expansion has increased the demand for warehouses. Steel construction is often the preferred choice because it allows for large, open spaces without obstructive support columns. This flexibility makes steel warehouses highly adaptable for different industries, ranging from retail distribution centers to manufacturing plants and cold storage facilities.

Key Features of Steel Warehouse Construction

One of the defining features of steel warehouse construction is its modular design. Prefabricated steel components can be manufactured off-site and then assembled quickly, reducing construction time significantly compared to traditional concrete structures. This efficiency allows businesses to become operational faster, an essential factor in competitive markets.

Steel warehouses also emphasize durability. Steel frames can endure heavy machinery, constant loading and unloading, and exposure to weather elements without deteriorating quickly. Additionally, many steel warehouses integrate modern insulation and ventilation systems to maintain energy efficiency, helping reduce operational costs in the long run.

The Role of Technology in Steel Warehouse Construction

Modern technology plays a vital role in enhancing steel warehouse construction. Building Information Modeling (BIM), for instance, allows architects and engineers to design warehouses with precision. By simulating every structural element in a digital model, builders can identify potential issues before construction begins.

Another important technological advancement is automated fabrication. Steel parts are now cut, shaped, and welded by computer-guided machinery, ensuring consistent quality and reducing human error. This not only speeds up production but also guarantees stronger, safer structures. Smart technologies such as integrated sensors and IoT systems are also being added to steel warehouses, allowing real-time monitoring of temperature, humidity, and structural integrity.

Real-World Examples of Steel Warehouse Construction

Amazon Distribution Centers

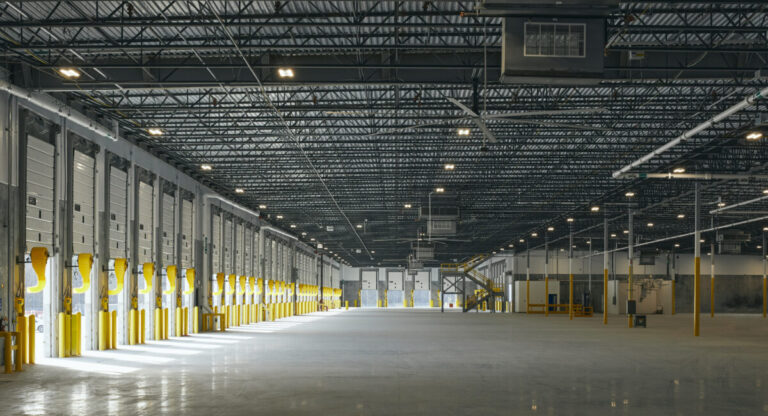

Amazon has revolutionized global logistics, and steel warehouse construction is at the core of its strategy. Many of Amazon’s fulfillment centers are massive steel structures designed for efficiency. Their warehouses often exceed 800,000 square feet, requiring clear-span construction without interior columns, something easily achievable with steel frameworks.

The use of steel allows Amazon to integrate advanced conveyor belts, robotics, and automated storage systems without structural limitations. These warehouses demonstrate how steel construction supports scalability, efficiency, and technological integration.

Tesla Manufacturing Storage Facilities

Tesla’s expansion in electric vehicle production has created a demand for steel warehouses. Many of Tesla’s facilities incorporate prefabricated steel structures to accommodate high-tech manufacturing equipment and storage of components.

Steel construction enables Tesla to design flexible layouts that adapt to rapid changes in technology and production needs. The durability of steel also ensures that heavy machinery, like robotic arms and battery assembly units, can operate without compromising the building’s structure.

Walmart Logistics Warehouses

Walmart operates one of the largest supply chains in the world, and steel warehouse construction is essential to maintaining its distribution network. These warehouses are designed to store vast quantities of inventory while ensuring efficient flow for loading and unloading trucks.

By using steel frameworks, Walmart can construct warehouses faster and expand them when needed. Their warehouses often feature integrated energy-saving systems, like solar panels and smart ventilation, highlighting the adaptability of steel buildings to sustainable practices.

Cold Storage Warehouses for Food Distribution

Cold storage warehouses require strict temperature control, and steel construction provides a reliable solution. Companies in the food and pharmaceutical industries rely on steel structures because they support insulated panels and advanced refrigeration systems effectively.

The durability of steel ensures the warehouse maintains airtight conditions for temperature-sensitive goods. These facilities highlight the versatility of steel warehouse construction across specialized industries.

Benefits of Steel Warehouse Construction

Steel warehouse construction offers a wide range of benefits that make it the preferred choice across industries. First, its cost-effectiveness is unmatched. Prefabricated steel components reduce labor costs and construction time, helping businesses achieve faster returns on investment.

Another benefit is sustainability. Steel is one of the most recyclable materials in the world, and using it in warehouses reduces the environmental impact of construction. Combined with green technologies like solar roofing or smart lighting systems, steel warehouses contribute to long-term energy efficiency.

Flexibility is another advantage. Steel structures allow for easy modifications, expansions, and upgrades. As businesses grow, they can adapt their warehouses without tearing down the entire structure, saving both time and resources.

Use Cases of Steel Warehouse Construction

Supporting E-commerce Growth

E-commerce businesses require warehouses that can handle rapid inventory turnover and complex logistics. Steel warehouse construction provides large, open floor plans that support automation systems like robotic pickers and conveyor belts, ensuring fast and efficient operations.

Manufacturing and Heavy Industry

For manufacturing companies, steel warehouses are ideal because they support heavy machinery and equipment. Steel structures can endure vibrations, loads, and continuous operations, making them suitable for automotive, aerospace, and industrial manufacturing.

Agricultural and Food Storage

Agricultural companies rely on steel warehouses for grain storage, food distribution, and refrigerated environments. The adaptability of steel buildings ensures that storage requirements, whether dry or cold, can be met efficiently without compromising product safety.

Emergency Response and Humanitarian Aid

Steel warehouses are also used by governments and NGOs as storage facilities for emergency supplies, such as food, medicine, and equipment. Their quick construction time makes them ideal for urgent situations where speed is critical.

Conclusion

Steel warehouse construction has transformed how businesses build, store, and operate across industries. From logistics giants like Amazon and Walmart to manufacturing leaders like Tesla, steel warehouses represent efficiency, strength, and adaptability. Their ability to integrate technology, support sustainable practices, and solve real-world challenges ensures they remain the top choice for modern industries.

FAQ

1. Why is steel preferred for warehouse construction over concrete?

Steel is preferred because it is faster to assemble, more flexible for design, and durable enough to handle heavy use. Unlike concrete, steel allows for large open spans without interior columns.

2. Can steel warehouses be expanded easily?

Yes, steel warehouses are modular in design, making them easy to expand or modify as a business grows, without requiring complete reconstruction.

3. Are steel warehouses energy efficient?

Steel warehouses can be highly energy efficient when combined with insulation, smart lighting, and renewable energy systems, making them both cost-effective and environmentally friendly.