Steel Warehouse Building Cost: Complete Guide to Pricing, Design, and Real-World Applications

Steel warehouse building cost refers to the total investment required to design, manufacture, and construct a warehouse made primarily from steel. These warehouses are widely used across industries due to their strength, durability, and cost-effectiveness. Compared to traditional concrete structures, steel warehouses often provide faster construction timelines and lower maintenance requirements.

The cost of a steel warehouse is influenced by multiple factors, including size, location, building design, material grade, and customization needs. Additionally, global steel prices and labor availability can affect overall expenses. Understanding these factors is crucial for businesses planning to invest in a new warehouse facility.

Key Factors Affecting Steel Warehouse Costs

Several core elements contribute to the overall steel warehouse building cost. Each of these factors should be evaluated during the planning phase.

Size and Dimensions

The larger the warehouse, the higher the material and labor costs. However, steel buildings often benefit from economies of scale, meaning larger projects may have a lower cost per square foot compared to smaller ones. Height also plays a role, especially if the design requires high bay storage systems.

Design Complexity

Simple rectangular structures are the most cost-efficient. However, customized designs with mezzanine floors, specialized loading bays, or additional architectural features increase both material use and construction complexity, which raises costs.

Location and Site Preparation

The cost of construction materials, permits, and labor varies significantly by region. Additionally, site preparation—such as land leveling, soil testing, and foundation work—adds to the budget.

Insulation and Energy Efficiency

Warehouses designed for temperature-sensitive products may require advanced insulation and climate control systems. These additions improve energy efficiency but also increase upfront construction costs.

Material Quality and Steel Prices

Steel grades, thickness, and protective coatings affect durability and cost. Since steel is a globally traded commodity, market fluctuations can significantly impact project budgets.

Benefits of Steel Warehouse Construction

Steel warehouses provide numerous advantages for businesses compared to traditional construction methods.

Durability and Longevity

Steel structures are highly resistant to weather, pests, and fire. This longevity reduces long-term maintenance costs and ensures reliable operation for decades.

Faster Construction Timelines

Prefabricated steel components allow warehouses to be built quickly. Faster timelines mean businesses can begin operations sooner, which directly translates into cost savings and quicker return on investment.

Flexibility and Scalability

Steel warehouses are highly customizable and can be expanded easily as business needs grow. Modular construction makes it possible to add new sections without disrupting ongoing operations.

Sustainability

Many steel warehouses use recycled materials and can be disassembled and reused. Energy-efficient insulation and renewable energy integration further reduce the environmental footprint.

Real-World Examples of Steel Warehouse Buildings

Butler Manufacturing Steel Warehouses

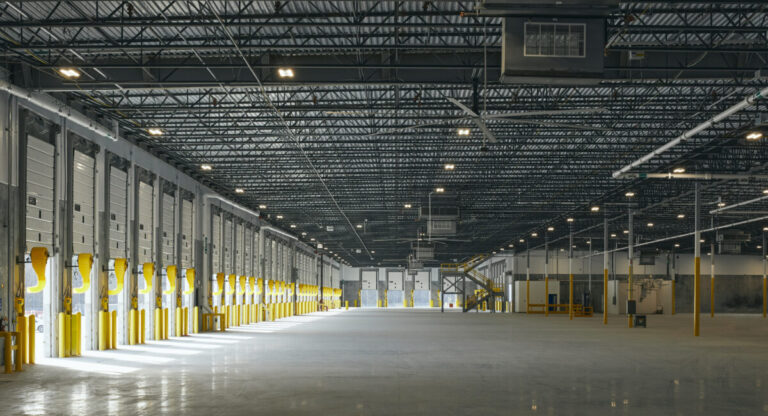

Butler Manufacturing is known for its prefabricated steel warehouses. Their buildings use energy-efficient designs and advanced roofing systems, which reduce heating and cooling costs. Butler facilities are popular with distribution companies that require large, clear-span spaces for equipment and inventory management.

Kirby Building Systems Industrial Warehouses

Kirby Building Systems specializes in steel warehouse construction for industrial clients. Their projects often incorporate custom loading docks and mezzanines. The company’s emphasis on design flexibility allows businesses to create efficient layouts tailored to their operational needs.

General Steel Metal Warehouses

General Steel is a leading provider of prefabricated steel buildings. Their warehouses are designed for scalability, making them ideal for businesses that anticipate growth. They often integrate insulated panels and energy-saving systems, lowering long-term operational costs.

Morton Buildings Steel Warehouses

Morton Buildings offers steel warehouses that combine durability with aesthetic appeal. Their projects often include insulated walls and advanced ventilation systems, making them suitable for both storage and light manufacturing applications.

Practical Use Cases of Steel Warehouses

Steel warehouses serve as critical infrastructure across multiple industries.

Logistics and Distribution

E-commerce growth has driven demand for steel warehouses that can handle high-volume storage and fast-moving inventory. Their large open spans allow for efficient racking systems and automated logistics solutions.

Agriculture and Farming

Farmers rely on steel warehouses for storing crops, equipment, and feed. The durability of steel structures protects assets from harsh weather conditions and pests, while flexible layouts allow for seasonal adjustments.

Manufacturing and Industrial Production

Steel warehouses are commonly used for production facilities. Their strength supports heavy machinery, and customizable layouts provide space for assembly lines, raw material storage, and finished goods.

Cold Storage and Food Supply Chain

With proper insulation, steel warehouses serve as reliable cold storage facilities for food and beverages. Their adaptable design allows for multiple temperature zones and energy-efficient climate control systems.

Challenges in Steel Warehouse Construction

While steel warehouses offer many benefits, they also present certain challenges. Initial costs can be high, especially when energy-efficient systems and advanced insulation are included. Additionally, fluctuations in steel prices create uncertainty in budgeting. Businesses must also ensure compliance with building codes, zoning laws, and safety regulations, which can extend project timelines.

Frequently Asked Questions

1. What is the average cost of building a steel warehouse?

Costs vary based on size, design, and location, but they typically range from $25 to $80 per square foot. More complex designs with insulation and climate control fall on the higher end of the spectrum.

2. How long does it take to build a steel warehouse?

Construction timelines can range from a few months to over a year, depending on the scale and complexity of the project. Prefabricated steel structures usually shorten the timeline significantly.

3. Why choose steel over concrete for warehouse construction?

Steel offers faster construction, easier scalability, and lower long-term maintenance. Unlike concrete, steel buildings can be easily modified or expanded, making them more adaptable for growing businesses.