Building a Cold Storage Warehouse: Complete Guide to Design, Technology, and Efficiency

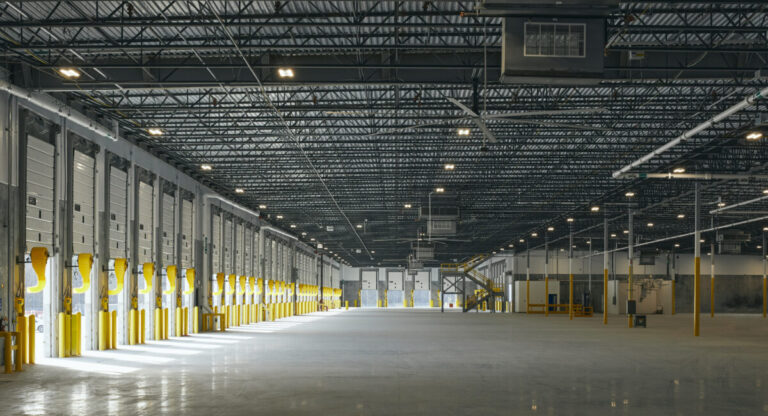

Building a cold storage warehouse requires careful planning, specialized design, and advanced technology integration to ensure temperature-sensitive goods are stored safely. These warehouses are critical for industries such as food, pharmaceuticals, and chemicals, where temperature fluctuations can directly impact product quality and safety.

Unlike conventional warehouses, cold storage facilities include insulated structures, advanced refrigeration systems, and humidity control mechanisms. They are designed not only to store perishable items but also to support efficient supply chain operations. The process of constructing one involves selecting the right building materials, incorporating advanced technology, and ensuring compliance with industry regulations.

Core Considerations in Building a Cold Storage Warehouse

Site Selection and Planning

Choosing the right location is the first step in building a cold storage warehouse. Proximity to suppliers, distribution centers, and transportation hubs ensures products can move quickly while minimizing logistical costs. Access to utilities, especially consistent electricity, is also crucial since cold storage operations rely heavily on uninterrupted power supply.

Planning should account for facility size, future expansion, and the types of products stored. A warehouse storing frozen seafood requires different design specifications compared to one storing fresh produce or pharmaceuticals.

Structural Design and Insulation

Cold storage warehouses must be built with specialized insulation to minimize temperature fluctuations. High-quality insulated metal panels, vapor barriers, and sealed flooring prevent energy loss and moisture infiltration. Structural integrity also plays a role in supporting heavy refrigeration systems, pallet racking, and automation equipment.

The building envelope walls, ceilings, and floors needs airtight sealing to maintain efficiency. Without proper insulation, energy costs rise, and product safety is compromised.

Refrigeration Systems

Refrigeration is the backbone of any cold storage warehouse. Depending on requirements, facilities can use blast freezers, chillers, or multi-temperature systems. For instance, frozen meat might need storage at -18°C, while fresh produce requires temperatures around 0–4°C.

Modern systems are designed with energy efficiency in mind, using advanced compressors, heat recovery systems, and environmentally friendly refrigerants. Backup generators and redundant refrigeration systems are essential to prevent product loss during power outages.

Technology Integration in Cold Storage Warehouses

IoT and Monitoring Systems

IoT-enabled temperature and humidity sensors provide real-time monitoring across the warehouse. These systems alert operators if temperatures deviate, reducing spoilage risks and ensuring compliance with safety standards.

Automation and Robotics

Automated storage and retrieval systems (ASRS) are becoming common in cold storage warehouses. Robotics reduces human exposure to extreme cold, improves accuracy, and optimizes space utilization. Automated pallet shuttles and conveyors further enhance material flow efficiency.

Energy-Efficient Systems

Cold storage facilities are energy-intensive. Implementing energy-efficient systems such as LED lighting, variable frequency drives (VFDs) for compressors, and solar panel integration reduces operational costs. Advanced insulation technologies also contribute to energy savings.

Real-World Examples of Cold Storage Warehouses

Lineage Logistics Cold Storage Facilities

Lineage Logistics operates some of the largest cold storage warehouses globally. Their facilities integrate advanced automation, robotics, and energy-efficient refrigeration systems. They also utilize data analytics to optimize inventory management and energy consumption.

Americold Cold Storage Solutions

Americold specializes in multi-temperature warehouses that accommodate both frozen and chilled products. Their facilities include automated systems for pallet handling and are strategically located near major transport routes, reducing distribution delays.

NewCold Automated Warehouses

NewCold operates fully automated cold storage warehouses powered by advanced ASRS systems. Their design reduces manual labor and maximizes vertical storage space, making operations more efficient and environmentally friendly.

United States Cold Storage (USCS)

USCS focuses on customer-driven solutions, offering flexible cold storage tailored to industry needs. Their facilities incorporate IoT-based monitoring systems and sustainable technologies to ensure operational reliability.

Benefits of Building a Cold Storage Warehouse

Enhanced Product Safety

Cold storage ensures perishable goods such as meat, dairy, seafood, and pharmaceuticals remain safe and effective. Temperature control reduces the risk of spoilage and contamination.

Supply Chain Efficiency

Integrating cold storage into supply chains minimizes delays, ensuring products move seamlessly from warehouse to retailer or end user. Proximity to distribution centers further enhances speed and reliability.

Operational Cost Savings

Although initial construction is costly, energy-efficient systems and automation reduce long-term expenses. Businesses also save by minimizing product loss and spoilage.

Compliance with Regulations

Building to industry standards ensures compliance with regulations such as HACCP and FDA requirements. Proper design and monitoring systems help businesses meet these strict guidelines consistently.

Practical Use Cases

Food Industry

Cold storage warehouses are critical for frozen food manufacturers, seafood distributors, and fresh produce suppliers. Facilities designed with multiple temperature zones allow for diverse product storage under one roof.

Pharmaceutical Storage

Vaccines, medicines, and biologics require strict temperature-controlled environments. A purpose-built cold storage warehouse ensures compliance with health regulations while maintaining product efficacy.

E-Commerce and Grocery Delivery

The rise of online grocery shopping has accelerated the demand for cold storage warehouses. Facilities enable same-day or next-day delivery of perishable goods while maintaining quality.

Logistics and Distribution Hubs

Third-party logistics companies use cold storage warehouses as central hubs for distributing perishable goods across regions. This reduces transportation costs and ensures freshness.

Challenges in Building a Cold Storage Warehouse

High Construction Costs

Cold storage facilities require specialized materials, advanced insulation, and high-capacity refrigeration systems. These factors make construction significantly more expensive than conventional warehouses.

Energy Consumption

Maintaining sub-zero temperatures consumes substantial energy. Facilities must incorporate sustainable practices to reduce environmental impact and operating costs.

Maintenance Requirements

Refrigeration equipment, insulation, and monitoring systems require regular maintenance to prevent failures. Downtime can lead to product losses worth millions of dollars.

Frequently Asked Questions

1. What is the most important factor when building a cold storage warehouse?

The most critical factor is proper insulation and refrigeration design. Without airtight construction and reliable systems, maintaining consistent temperatures becomes difficult, risking product quality and safety.

2. How do cold storage warehouses reduce energy costs?

By using energy-efficient refrigeration systems, LED lighting, advanced insulation, and automation, cold storage warehouses minimize power consumption while maintaining required conditions.

3. Which industries benefit the most from cold storage warehouses?

Industries such as food and beverage, pharmaceuticals, chemicals, and e-commerce benefit the most. These facilities ensure perishable and sensitive products are stored and distributed safely.