Bulk Storage Warehouse: Ultimate Guide to High-Capacity Storage Solutions

Bulk storage warehouses are specialized facilities designed to store large quantities of products, raw materials, or goods efficiently. These warehouses are critical for industries such as logistics, retail, manufacturing, and agriculture, providing scalable and organized storage solutions.

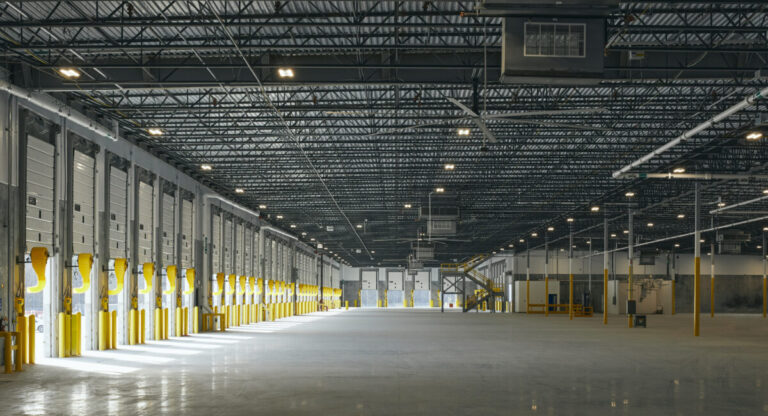

Unlike conventional warehouses, bulk storage warehouses focus on maximizing storage density while maintaining accessibility for forklifts and heavy machinery. They allow businesses to store significant volumes of goods without sacrificing operational efficiency or safety.

High-bay racking systems, reinforced flooring, and strategically planned layouts make bulk storage warehouses an essential component of modern supply chains.

Key Features of Bulk Storage Warehouses

Bulk storage warehouses include several key features designed to optimize storage and logistics:

- High-Density Storage: Utilizing vertical space with tall racking systems and mezzanine levels increases storage capacity while maintaining organized inventory.

- Heavy-Duty Infrastructure: Reinforced floors and structural supports accommodate heavy loads and industrial equipment safely.

- Flexible Layouts: Open floor plans allow adjustments for different types of inventory, equipment, and operational requirements.

- Efficient Loading and Unloading Areas: Dock doors, wide aisles, and forklift paths enable seamless handling of large shipments.

- Climate Control Systems: Temperature-controlled environments protect sensitive or perishable goods, ensuring product quality.

These features make bulk storage warehouses ideal for businesses handling high-volume inventories with diverse storage needs.

Advantages of Bulk Storage Warehouses

Operational Efficiency

Bulk storage warehouses streamline inventory management by consolidating large quantities in one location. This reduces the need for frequent shipments, speeds up order processing, and allows for smooth movement of goods throughout the supply chain.

Cost Optimization

High-density storage reduces the cost per unit of storage. Combined with automated handling systems, businesses can minimize labor costs, optimize warehouse space, and reduce operational expenses significantly.

Technology Integration

Modern bulk warehouses often incorporate Warehouse Management Systems (WMS), automated retrieval systems, and RFID tracking. These technologies improve inventory accuracy, enable real-time monitoring, and reduce human errors.

Scalability

Bulk storage warehouses are designed to accommodate future growth. Modular racking systems, high ceilings, and flexible layouts allow businesses to expand storage capacity without major renovations or downtime.

Real-World Examples of Bulk Storage Warehouses

Amazon Fulfillment Centers

Amazon’s bulk storage warehouses are engineered to handle millions of items across various categories. High-bay racking and automated retrieval systems enable fast order fulfillment and precise inventory management. This example demonstrates how technology integration in bulk storage can significantly enhance operational efficiency.

Walmart Regional Distribution Centers

Walmart uses bulk storage warehouses to supply multiple retail locations. Reinforced floors, wide aisles, and automated forklifts ensure safe handling of bulk shipments. These facilities optimize logistics and inventory management, supporting a large-scale retail operation.

Cargill Agricultural Storage Facilities

Cargill’s warehouses for grains and oilseeds include silos, conveyor belts, and climate control systems. Bulk storage solutions minimize spoilage, improve storage efficiency, and streamline distribution for agricultural products.

DHL E-Commerce Warehouses

DHL’s bulk warehouses for e-commerce inventory use automated sorting and high-density racks. This setup ensures rapid handling of large shipment volumes, improving delivery times and operational efficiency.

Technology Advantages in Bulk Storage Warehouses

Warehouse Management Systems

WMS software tracks inventory, locations, and movements in real-time, reducing errors and improving stock visibility.

Automated Storage and Retrieval Systems

Robotic ASRS systems retrieve and store goods efficiently in high-density racks, increasing throughput and minimizing manual labor.

RFID and IoT Integration

Radio-frequency identification and IoT devices enable precise tracking and monitoring of inventory across multiple warehouse locations.

Energy Efficiency

LED lighting, solar panels, and optimized HVAC systems reduce operational costs while improving environmental sustainability.

Technology integration allows bulk storage warehouses to remain competitive, scalable, and productive.

Practical Use Cases

E-Commerce Fulfillment

E-commerce companies rely on bulk warehouses to store high volumes of products. Structured storage and efficient handling ensure rapid order fulfillment and minimal delays.

Food and Beverage Storage

Perishable products require climate-controlled bulk warehouses. Temperature and humidity regulation, along with rapid handling, maintain product quality and compliance with safety standards.

Industrial and Manufacturing Storage

Manufacturers store raw materials and finished goods in bulk warehouses. Reinforced structures and automated equipment allow efficient handling of heavy or oversized products.

Third-Party Logistics Providers

3PL companies use bulk storage warehouses to manage multiple clients’ inventories. Flexible layouts and automated systems provide cost-effective storage and streamlined order management.

Benefits for Business Operations

Businesses using bulk storage warehouses can achieve:

- Increased storage capacity and organized inventory management

- Reduced operational costs with optimized layouts and automation

- Faster order fulfillment and improved supply chain efficiency

- Scalability for future growth

- Enhanced safety and compliance with industry standards

Bulk storage warehouses provide strategic advantages for businesses handling high-volume inventory.

Frequently Asked Questions

1. How does a bulk storage warehouse differ from a standard warehouse?

Bulk storage warehouses focus on high-density, high-volume storage, reinforced infrastructure, and optimized layouts for machinery and forklifts. Standard warehouses typically handle smaller inventories and have less emphasis on high-capacity storage.

2. Can bulk storage warehouses use automation?

Yes, modern bulk warehouses often integrate automated storage and retrieval systems (ASRS), conveyors, and warehouse management software to improve efficiency and reduce labor requirements.

3. Why are bulk storage warehouses important for supply chain management?

They enhance inventory management, reduce storage costs, improve order fulfillment speed, and allow businesses to efficiently handle large volumes of goods in a structured and scalable manner.