Steel Warehouse Buildings: Design, Cost, and Benefits Explained

Steel warehouse buildings have become the backbone of modern logistics, manufacturing, and distribution industries. Their durability, adaptability, and cost-effectiveness make them one of the most popular choices for businesses that require large storage and operational spaces. Unlike traditional construction methods, steel offers scalability and structural strength, ensuring that warehouses can withstand heavy use while remaining flexible for future expansion.

The increasing demand for fast-moving supply chains, e-commerce operations, and global distribution has also driven interest in steel warehouses. Companies now prioritize construction options that minimize downtime, maximize usable space, and reduce long-term maintenance costs, all areas where steel buildings excel.

Why Steel is Preferred for Warehouse Construction

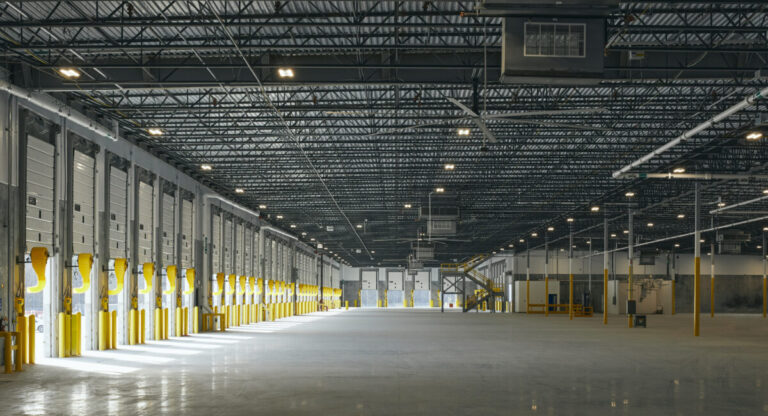

Steel offers several advantages compared to concrete, brick, or wood. One of the primary benefits is its structural resilience. A steel frame can support large spans without the need for multiple interior columns, allowing businesses to maximize floor space efficiency.

Another critical factor is sustainability. Steel is recyclable, which reduces environmental impact. Many companies building warehouses today are pursuing green certifications, and steel construction provides an eco-friendly path without compromising on durability.

Key Design Considerations for Steel Warehouse Buildings

Designing a steel warehouse involves much more than erecting a simple structure. Considerations include the purpose of the warehouse, the type of inventory stored, and the operational flow inside the building. High-bay designs, for example, allow for more vertical storage, while wide-span designs cater to industries that require unobstructed floor areas.

Insulation and climate control are also major considerations. A warehouse that stores perishable goods or sensitive materials will need advanced HVAC systems, insulation panels, and ventilation. Structural elements such as skylights and translucent panels can also help reduce energy consumption, making steel warehouses more cost-efficient over time.

Cost Factors in Steel Warehouse Buildings

Steel warehouse building costs vary significantly depending on size, location, and design complexity. A basic prefabricated steel warehouse may cost less upfront, while customized warehouses with climate control, heavy-duty flooring, and advanced racking systems can be considerably more expensive.

Labor costs, foundation work, insulation, and finishing touches like office space integration also impact the overall price. However, steel warehouses generally have lower lifecycle costs due to their durability and low maintenance requirements compared to traditional materials.

Real-World Examples of Steel Warehouse Buildings

Amazon Fulfillment Centers

Amazon has invested heavily in steel warehouse construction across the globe. These fulfillment centers are designed for automation, robotics, and high-volume order processing. Steel framing allows for large, open layouts where conveyor systems, storage racks, and robotics can operate without obstruction.

The scalability of steel warehouses has enabled Amazon to rapidly expand its footprint and adapt to ever-changing logistics demands. This model demonstrates how steel construction supports e-commerce giants in meeting fast delivery expectations.

Tesla Gigafactory Storage Facilities

Tesla relies on steel warehouse buildings for storing automotive parts, batteries, and equipment near its Gigafactories. These warehouses must be durable and flexible to house large machinery and sensitive electronic components.

Steel construction allows Tesla to quickly scale its operations while ensuring safety and efficiency. The warehouses often include advanced ventilation, insulation, and fire protection systems, making them a prime example of steel adaptability.

Walmart Distribution Centers

Walmart distribution centers use massive steel structures to support their retail supply chains. These warehouses often feature wide-span steel beams that create uninterrupted floor spaces for efficient truck loading, pallet handling, and sorting systems.

The modular nature of steel warehouses allows Walmart to expand or modify facilities without major reconstruction. This approach highlights how steel supports operational efficiency and scalability in retail logistics.

Cold Storage Steel Warehouses

Companies specializing in food logistics rely on steel warehouses with integrated cold storage capabilities. Steel buildings can be fitted with insulated panels, refrigeration systems, and moisture-resistant materials to maintain low temperatures.

This setup ensures the preservation of perishable goods while minimizing energy consumption. Cold storage warehouses built with steel frames highlight the adaptability of this material in specialized industries.

Benefits of Steel Warehouse Buildings

Durability and Longevity

Steel warehouses are highly resistant to weather conditions, pests, fire, and natural wear. This makes them more durable than wood or brick structures, reducing repair and replacement costs over decades of use.

Faster Construction Time

Prefabricated steel components allow for quicker assembly compared to traditional construction. This results in reduced project timelines, enabling businesses to start operations sooner and cut down on overhead costs during construction delays.

Cost-Effectiveness

Although initial costs may vary, the long-term savings from lower maintenance, energy efficiency, and expansion flexibility make steel warehouse buildings cost-effective investments.

Sustainability

Steel is one of the most recyclable construction materials. Using steel for warehouses helps companies meet sustainability goals while supporting environmental initiatives.

Use Cases for Steel Warehouse Buildings

E-commerce Fulfillment

The e-commerce boom has created high demand for steel warehouses that can accommodate automated storage and retrieval systems. Steel structures support the flexibility and scalability required for fast-moving online retail logistics.

Manufacturing Storage

Manufacturing industries use steel warehouses to store raw materials and finished products. The ability to integrate cranes, heavy machinery, and reinforced flooring makes steel buildings ideal for industrial use.

Agriculture and Food Distribution

Farmers and food distributors use steel warehouses for storing grains, produce, and refrigerated products. With climate control options, steel warehouses can maintain optimal storage conditions, reducing spoilage and waste.

Automotive and Aerospace

Industries like automotive and aerospace depend on steel warehouses for storing parts, machinery, and large-scale equipment. The open-span design of steel buildings allows easy access and efficient handling of oversized items.

Challenges in Steel Warehouse Buildings

While steel warehouses offer many benefits, challenges include upfront investment costs, potential corrosion in certain climates if not maintained properly, and the need for specialized labor during construction. Addressing these issues with proper design and protective coatings ensures long-term efficiency.

Conclusion

Steel warehouse buildings are transforming how businesses approach storage and distribution. With their durability, scalability, and adaptability, they provide a long-term solution for industries ranging from e-commerce to agriculture. Real-world examples demonstrate how steel continues to be a critical element in logistics infrastructure.

FAQs

1. What is the lifespan of a steel warehouse building?

A properly maintained steel warehouse can last 40–60 years or more, depending on environmental conditions and upkeep.

2. Are steel warehouses customizable?

Yes, steel warehouses can be customized for size, layout, insulation, and specialized features such as refrigeration or mezzanine office spaces.

3. How do steel warehouses compare to concrete warehouses?

Steel warehouses are generally faster to build, more flexible for expansion, and often more cost-efficient in the long term, while concrete may provide additional thermal mass and fire resistance in certain applications.